However, with the rapid increase of spare parts types, the complexity of aircraft parts multi-stage supply chains leads to inefficient tracing and tracking operations with unsatisfactory traceability data quality and information security. The International Air Transport Association (IATA) has strongly emphasised the significance of quality traceability data throughout the aircraft part’s life cycle, leading to enhanced inventory control accuracy, reduced maintenance error, and effective decision-making processes. Traceability and trackability of data ensure the compliance of airworthiness requirements.

By focusing on AIM which is a key element of PSM, it will be possible to gain a better understanding of one of the most significant and problematic sources of risk in process safety.Īircraft spare parts inventory management (ASPM) has played a critical role in tracing and tracking spare parts as any related maintenance or movement shall be recorded. Additionally, there must be a greater emphasis placed on the impact of human factors as they are directly (23.58%) and indirectly (11.10%) responsible for accidents as well as other technological malfunctions. Four factors related to assets, including construction, testing, inspection, and maintenance, account for more than half the incidents (54.78%). The findings of these techniques point towards the same results for reducing incident rates. To analyze the relationships between the different factors of AIM, two score-based (Tabu and Hill Climbing) and one hybrid (Max-Min Hill-Climbing) Bayesian networks are used to develop one final viable solution. In this study, AIM is divided into 2 major groups – asset and human factors – and then, in order to get more detailed results, each group is divided into 9 and 5 subcategories, respectively. This systematic approach can improve AIM to better understand PSM as a whole and the underlying dynamics ever-present in the system. The purpose of the current study is to control and minimize the total number of incidents that occur within an oil and gas operation by applying a multidisciplinary approach to explore and develop AIM. We combine expert knowledge and data analytics (Artificial Intelligence, Machine Learning, and Keyword Analysis) to create a reaction network for Asset Integrity Management (AIM) and provide a theoretical and practical basis for handling uncertainty in large data sets such as company incident databases. Asset integrity and reliability is one of the 20 elements of Process Safety Management (PSM) as defined by the Center for Chemical Process Safety (CCPS). Express your creativity with nearly limitless features including photo editing, collage making, digital drawing and more! With.

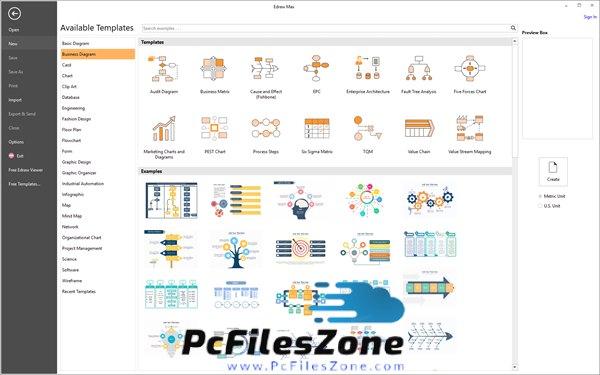

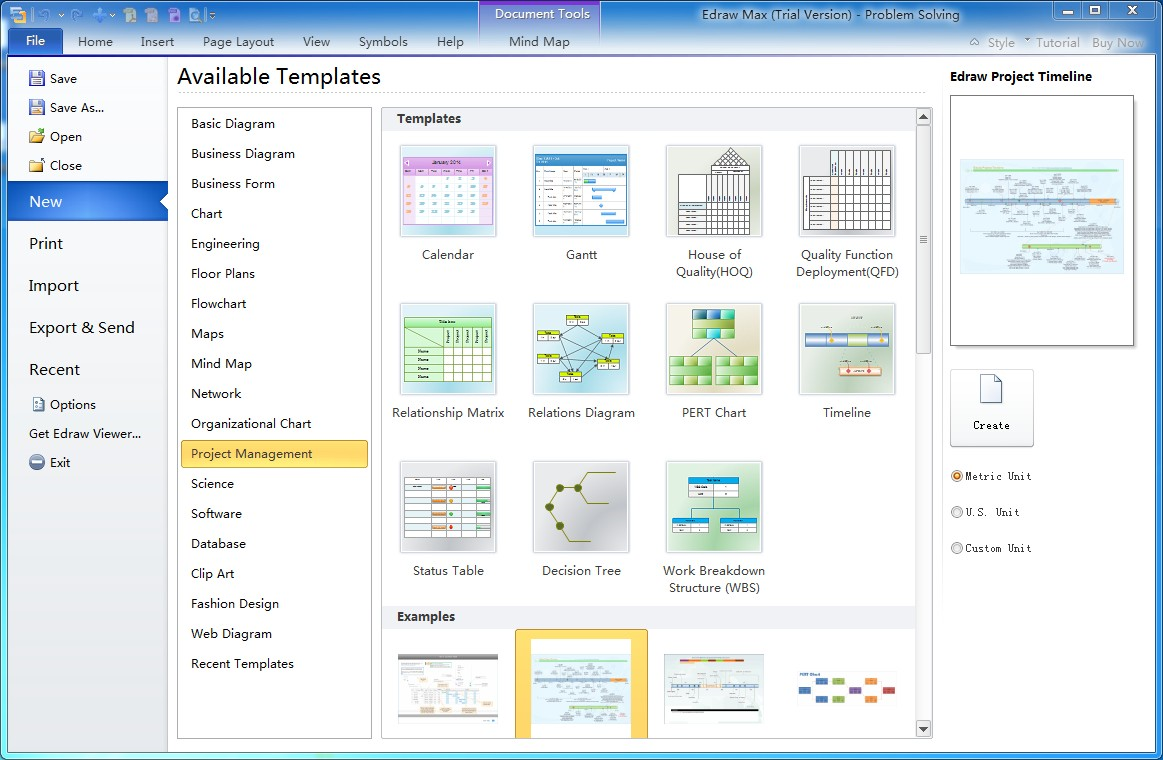

#EDRAW PROJECT MANAGEMENT SOFTWARE#

Top Software Keywords Show more Show lessĤ00 million+ installs strong, PicsArt is a powerful photo editor, collage maker, drawing tool, and the #1 all-in-one photo app for Windows. photo to video photo to avi photo to divx photo to rm photo to wmv photo to mpg.

0 kommentar(er)

0 kommentar(er)